PVD color coating is a process of physical vapor deposition, also known as PVD coating. This process involves forming ultra-thin films of chromium, titanium, ammonia, or other specially treated alloys on various metals and plastics.

PVD-coated stainless steel coils are an effective process that uses physical vapor deposition to cover the surface of stainless steel coils with titanium ion plating. This layer enhances the durability and corrosion resistance of stainless steel coils while also providing an aesthetically pleasing finish.

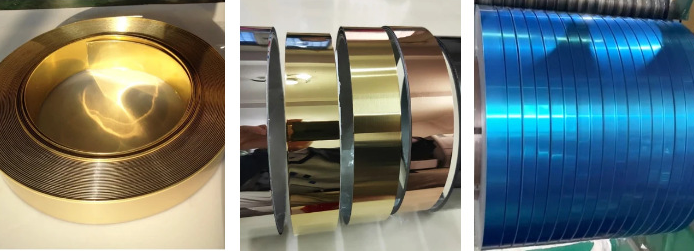

PVD color coatings are available in a variety

of colors, including gold, rose gold, black, champagne, sapphire blue, emerald green, purple, copper, rainbow, and dark gray, to enhance the appearance of your products. Each color has a unique appearance, creating a specific aesthetic for the product that cannot be achieved with powder paint alone.

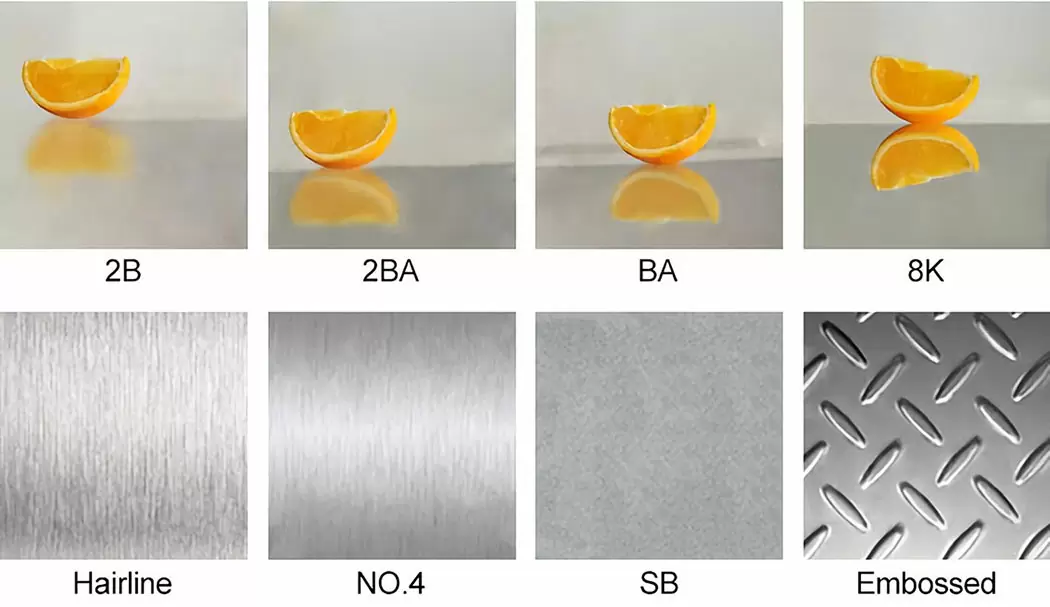

PVD coatings offer a wide range of colors beyond those listed and can be customized to meet individual needs. Furthermore, multi-layer PVD technology provides durable and superior color that can withstand more damage than many traditional surface treatments, such as sandblasting, mirror polishing, and brushing.

PVD coating technology has been applied to stainless steel panels for many years and has proven to be reliable.

Innovators have recently started using the same method to coat stainless steel coils.

The coils are cut into small pieces to form plates with standard sizes of 1219*2438mm and 1219*3048mm, or customized specifications. The entire roll can be hundreds of meters long, with a maximum thickness of 1500mm.

Our stainless steel panels can be painted in all PVD colors, with the option for single or double-sided plating.

Currently, stainless steel coils are only available in limited colors due to technological limitations.

However, engineers are researching and developing new colors for the coils, so more options will be available in the near future.

Please note that we prioritize work efficiency.

The number of pieces that can be coated at one time varies depending on the type of plating. Suspended and horizontal PVD sheet vacuum chambers are relatively small and can only coat 3-8 films at a time, while sheet 4ftx8ft.

However, when it comes to spools that are often hundreds of meters long, we have to be especially careful during the setup process: if not configured properly beforehand, the final color may be uneven or very different from what was originally intended – by which time it’s too late!

Potential Risks

Moving the boards into the vacuum oven must be done by hand, and if not done carefully, the process can leave horseshoe marks on the fragile boards, which are typically less than 0.8 mm thick.

On the other hand, because of the automated production process, the stainless steel coils are not affected by any human issues,

It is also important to consider that the risks associated with sheet metal can be minimized if the operator takes extra care and attention during handling. Ultimately, both sheet and coil have their own advantages and disadvantages in terms of potential risks, and it is up to the user to decide which material is best for their application,

Regardless of the choice, users should be aware of the potential risks associated with handling stainless steel materials to ensure a successful outcome.

Advantages of using PVD color coated stainless steel coils

Environmentally friendly

The coating process contains no hazardous chemicals and requires no painting or plating, reducing carbon emissions and carbon footprint.

Durable and long lasting

The PVD coating is resistant to wear and corrosion, ensuring the color is long-lasting.

Reduced cost

-Coating the entire coil in one pass reduces cost and time, eliminating the need for additional

Additional post-coating process

Trusted PVD coated stainless steel sheet/coil supplier for your needs

With a proven track record of innovation and quality, WAYEN has been delivering projects for over 10 years, providing exceptional products and unparalleled service levels. Our customers can be confident that they are getting the best product for their needs every time.

As an experienced PVD coated stainless steel sheet/coil supplier, we fully understand our customers’ needs and provide tailor-made solutions.

All of our processes are designed with safety and sustainability in mind, so you can rest assured that your products are responsibly sourced while maintaining the highest quality standards.

Our team works hard to ensure that all of our products meet the highest quality and technical requirements, with full traceability of everything we make. We also understand that there are many personal preferences when it comes to product selection, which is why we offer a wide range of different finishes, colors and textures to choose from.

At WAYEN, we strive to be a trustworthy supplier of PVD coated stainless steel sheets/coils that you can rely on. With excellence in quality and service at our core, you can count on us to deliver exceptional solutions every time. Contact us today to learn more about our products and services or to request a free sample. We’ll be happy to help you find the perfect solution for your needs.

Please feel free to email us at salepc@wayenind.com or call us at 0086 13106681701/WA:0086 13590571866. We look forward to helping you with your next project!